Hot Online

400-027-6688

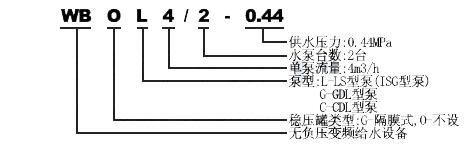

Model significance

Product profile

Water is the source of human life, human survival can not be a day without water.

As China's urbanization level enhances unceasingly, the city population increased dramatically, the continuous expansion and transformation of city residential, residential floors continuously increasing, city area continues to expand, the original municipal pipeline pressure inadequate. Most widespread water peak high water pressure is too low, with high water users difficult. So most of the buildings added two pressurized equipment, building water and high water tank, can pump the two pressurized water supply, but the traditional two pressurized equipment investment, easy water pollution two and so many shortcomings.

WB my company development and production of non negative pressure water supply equipment can be connected in series in the urban administration online to the user does not need to build a reservoir, high water tank, a two pressurized water supply equipment, directly connected in series with the municipal pipe network to the normal operation of the equipment will not form a negative pressure (water), the municipal network is fully in line with the China's "city water supply Ordinance" requirements, can make full use of the original pressure of the municipal pipe network, water supply by way of energy saving effect is extremely remarkable. After the market has been favored by large users.

Equipment characteristics

1, no need to set the reservoir and high water tank

Non negative pressure water supply equipment is directly connected in series with the municipal pipe network, no need to build a reservoir and water tank, save the project investment, reduce the occupied area of the building. When the municipal water supply pipe network enough, the non negative pressure steady flow tank volume is small, a small area of the whole set of equipment, equipment installation only connected to the pipe can be very convenient.

2, no two pollution sources in the non negative pressure steady flow tank and a series of equipment pipeline were closed, from the municipal network until the user taps are not two pollution by impurities in the air and dirt, non negative pressure steady flow tank flow source parts are used for inner wall of food container coating preservative treatment, coating and the negative pressure water supply equipment are in line with the relevant standards of food hygiene.

3, the energy saving effect is remarkable the traditional two pressurized water supply by way of the reservoir and the high water tank, the municipal water supply pipe network pressure in the reservoir of energy loss, serious waste of energy. Non negative pressure steady flow tank, the municipal water supply pipe network pressure superposition in imported feed water pump, water pump to supplement the pressure of the municipal pipe network, the energy saving effect is remarkable.

4, no need to set up the pressure pump and large volume tank

The general water supply equipment in order to ensure to avoid frequently starting pump leakage of small flow water users at night or zero flow pipe, pump and a large volume of air pressure tank are provided with the small flow rate, which increased the investment of water supply equipment, also increases the equipment operating costs (power consumption evening pump).

The evening peak when the water is low, water supply and water supply pressure of municipal pipe network to meet the basic requirements of users, using WB type non negative pressure water supply equipment, the original pressure of municipal pipe network is fully utilized, water is supplied directly to the municipal pipe network users use WB type non negative pressure water supply equipment and equipment without pump volume regulator pressure tank, saving investment, and increase WB non negative pressure water supply equipment operation energy saving effect when the.

work environment

1, the power supply voltage fluctuation less than 10%;

2, ambient temperature: -10 C - +40 C (not frozen);

3, relative humidity: 20% - 90% (no condensation);

4, absolute altitude: less than 1000m;

5, no conductive dust in Egypt can corrode the metal and the destruction of insulating gas;

6, no explosive danger place;

7, vibration: < 5.9m/s2 (0.6G): less than 5 degrees, the inclination of the place;

8, waterproof shockproof equipment and dry steam places;

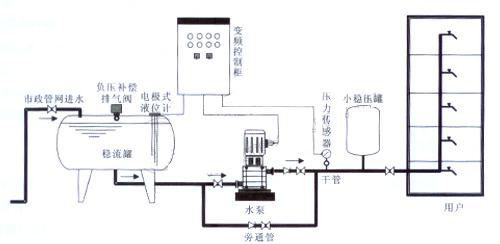

Working principle

WB type non negative pressure water supply equipment normally put into use, the municipal pipe network of water into the non negative pressure steady flow tank, a tank of air discharged from the exhaust valve. When the air is discharged, the valve ball is floating in water, driving the plug to the closed position, slowly close the exhaust port, to stop the exhaust, to prevent water, when the water flow in the steady flow tank normal transportation, such as a small amount of air accumulation to a considerable extent on the valve, the valve in the water level drops, the float with the decline of at this time, the air from the air outlet.

WB type non negative pressure water supply equipment in the process of the normal operation, when the municipal pipe network of water shortage, municipal water flow air pipe, or steady flow tank internal water pressure below atmospheric pressure, the water level in the stable current tank drops, the floating ball drops, drives the plug head open, inhalation of air, to maintain steady flow of atmospheric pressure inside the tank no, to produce negative pressure of the municipal pipe network.

When the pressure of the municipal pipe network is lower than the set pressure required by the user, the frequency conversion speed regulation of the water pump can ensure that the pressure of the pipe network meets the requirements of users. The higher the pressure of municipal pipe network. The lower the speed of the pump, the lower the pressure of the municipal pipe network, the higher the speed of the pump. When the municipal pipe network water supply pressure to meet the requirements of the user, WB type non negative pressure water supply equipment automatically stop working, municipal pipe network water directly through the bypass pipe supply to the user.

When the municipal network water supply, the water level in the stable current tank gradually decreased, when the water level dropped to the lowest level, the steady flow tank to the stop signal, WB type non negative pressure water supply equipment automatically stop operation and display water protection signal.

When the power grid blackout, WB type non negative pressure water supply equipment shutdown, municipal pipe network water directly from the WB type non negative pressure water supply equipment bypass pipe supply to the user.

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

1 | WBOC2/2-0.30 | 4 | 30 | CDL2-40 | 0.55 | WLG600-1000 | 0.25 | SYB-S0.55-2V |

2 | WBOC2/2-0.37 | 4 | 37 | CDL2-50 | 0.55 | WLG600-1000 | 0.25 | SYB-S0.55-2V |

3 | WBOC2/2-0.45 | 4 | 45 | CDL2-60 | 0.75 | WLG600-1000 | 0.25 | SYB-S0.75-2V |

4 | WBOC2/2-0.52 | 4 | 52 | CDL2-70 | 0.75 | WLG600-1000 | 0.25 | SYB-S0.75-2V |

5 | WBOC2/2-0.67 | 4 | 67 | CDL2-90 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-2V |

6 | WBOC2/2-0.82 | 4 | 82 | CDL2-110 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-2V |

7 | WBOC2/2-1.12 | 4 | 112 | CDL2-150 | 1.5 | WLG600-1000 | 0.25 | SYB-S1.5-2V |

8 | WBOC2/2-1.35 | 4 | 135 | CDL2-180 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

9 | WBOC4/2-0.32 | 8 | 32 | CDL4-40 | 0.75 | WLG600-1000 | 0.25 | SYB-S0.75-2V |

10 | WBOC4/2-0.40 | 8 | 40 | CDL4-50 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-2V |

11 | WBOC4/2-0.48 | 8 | 48 | CDL4-60 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-2V |

12 | WBOC4/2-0.64 | 8 | 64 | CDL4-80 | 1.5 | WLG600-1000 | 0.25 | SYB-S1.5-2V |

13 | WBOC4/2-0.80 | 8 | 80 | CDL4-100 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-2V |

14 | WBOC4/2-0.96 | 8 | 96 | CDL4-120 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-2V |

15 | WBOC4/2-1.28 | 8 | 128 | CDL4-160 | 3 | WLG600-1000 | 0.25 | SYB-S3-2V |

16 | WBOC4/2-1.52 | 8 | 152 | CDL4-190 | 4 | WLG600-1000 | 0.25 | SYB-S4-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

17 | WBOC8/2-0.36 | 16 | 36 | CDL8-40 | 1.5 | WLG800-1300 | 0.58 | SYB-S1.5-2V |

18 | WBOC8/2-0.45 | 16 | 45 | CDL8-50 | 2.2 | WLG800-1300 | 0.58 | SYB-S2.2-2V |

19 | WBOC8/2-0.54 | 16 | 54 | CDL8-60 | 2.2 | WLG800-1300 | 0.58 | SYB-S2.2-2V |

20 | WBOC8/2-0.72 | 16 | 72 | CDL8-80 | 3 | WLG800-1300 | 0.58 | SYB-S3-2V |

21 | WBOC8/2-0.90 | 16 | 90 | CDL8-100 | 4 | WLG800-1300 | 0.58 | SYB-S4-2V |

22 | WBOC8/2-1.08 | 16 | 108 | CDL8-120 | 4 | WLG800-1300 | 0.58 | SYB-S4-2V |

23 | WBOC8/2-1.26 | 16 | 126 | CDL8-140 | 5.5 | WLG800-1300 | 0.58 | SYB-S5.5-2V |

24 | WBOC8/2-1.44 | 16 | 144 | CDL8-160 | 5.5 | WLG800-1300 | 0.58 | SYB-S5.5-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

25 | WBOC16/2-0.36 | 32 | 36 | CDL16-30 | 3 | WLG1000-1600 | 1.1 | SYB-S3-2V |

26 | WBOC16/2-0.48 | 32 | 48 | CDL16-40 | 4 | WLG1000-1600 | 1.1 | SYB-S4-2V |

27 | WBOC16/2-0.60 | 32 | 60 | CDL16-50 | 5.5 | WLG1000-1600 | 1.1 | SYB-S5.5-2V |

28 | WBOC16/2-0.72 | 32 | 72 | CDL16-60 | 5.5 | WLG1000-1600 | 1.1 | SYB-S5.5-2V |

29 | WBOC16/2-0.84 | 32 | 84 | CDL16-70 | 7.5 | WLG1000-1600 | 1.1 | SYB-S7.5-2V |

30 | WBOC16/2-0.96 | 32 | 96 | CDL16-80 | 7.5 | WLG1000-1600 | 1.1 | SYB-S7.5-2V |

31 | WBOC16/2-1.20 | 32 | 120 | CDL16-100 | 11 | WLG1000-1600 | 1.1 | SYB-S11-2V |

32 | WBOC16/2-1.44 | 32 | 144 | CDL16-120 | 11 | WLG1000-1600 | 1.1 | SYB-S11-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

33 | WBOG2/3-0.36 | 6 | 36 | 25GDL2-12×3 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-3V |

34 | WBOG2/3-0.48 | 6 | 48 | 25GDL2-12×4 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-3V |

35 | WBOG2/3-0.60 | 6 | 60 | 25GDL2-12×5 | 1.5 | WLG600-1000 | 0.25 | SYB-S1.5-3V |

36 | WBOG2/3-0.72 | 6 | 72 | 25GDL2-12×6 | 1.5 | WLG600-1000 | 0.25 | SYB-S1.5-3V |

37 | WBOG2/3-0.84 | 6 | 84 | 25GDL2-12×7 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-3V |

38 | WBOG2/3-0.96 | 6 | 96 | 25GDL2-12×8 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-3V |

39 | WBOG2/3-1.08 | 6 | 108 | 25GDL2-12×9 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-3V |

40 | WBOG2/3-1.20 | 6 | 120 | 25GDL2-12×10 | 3 | WLG600-1000 | 0.25 | SYB-S3-3V |

41 | WBOG2/3-1.32 | 6 | 132 | 25GDL2-12×11 | 3 | WLG600-1000 | 0.25 | SYB-S3-3V |

42 | WBOG2/3-1.44 | 6 | 144 | 25GDL2-12×12 | 3 | WLG600-1000 | 0.25 | SYB-S3-3V |

43 | WBOG2/3-1.56 | 6 | 156 | 25GDL2-12×13 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

44 | WBOG2/3-1.68 | 6 | 168 | 25GDL2-12×14 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

45 | WBOG2/3-1.80 | 6 | 180 | 25GDL2-12×15 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

46 | WBOG4/3-0.33 | 12 | 33 | 25GDL4-11×3 | 1.1 | WLG600-1000 | 0.25 | SYB-S1.1-3V |

47 | WBOG4/3-0.44 | 12 | 44 | 25GDL4-11×4 | 1.5 | WLG600-1000 | 0.25 | SYB-S1.5-3V |

48 | WBOG4/3-0.55 | 12 | 55 | 25GDL4-11×5 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-3V |

49 | WBOG4/3-0.66 | 12 | 66 | 25GDL4-11×6 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-3V |

50 | WBOG4/3-0.77 | 12 | 77 | 25GDL4-11×7 | 3 | WLG600-1000 | 0.25 | SYB-S3-3V |

51 | WBOG4/3-0.88 | 12 | 88 | 25GDL4-11×8 | 3 | WLG600-1000 | 0.25 | SYB-S3-3V |

52 | WBOG4/3-0.99 | 12 | 99 | 25GDL4-11×9 | 3 | WLG600-1000 | 0.25 | SYB-S4-3V |

53 | WBOG4/3-1.10 | 12 | 110 | 25GDL4-11×10 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

54 | WBOG4/3-1.21 | 12 | 121 | 25GDL4-11×11 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

55 | WBOG4/3-1.32 | 12 | 132 | 25GDL4-11×12 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

56 | WBOG4/3-1.43 | 12 | 143 | 25GDL4-11×13 | 4 | WLG600-1000 | 0.25 | SYB-S4-3V |

57 | WBOG4/3-1.54 | 12 | 154 | 25GDL4-11×14 | 5.5 | WLG600-1000 | 0.25 | SYB-S5.5-3V |

58 | WBOG4/3-1.65 | 12 | 165 | 25GDL4-11×15 | 5.5 | WLG600-1000 | 0.25 | SYB-S5.5-3Vn |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

59 | WBOG6/3-0.36 | 18 | 36 | 40GDL6-12×3 | 1.5 | WLG800-1300 | 0.58 | SYB-S1.5-3V |

60 | WBOG6/3-0.48 | 18 | 48 | 40GDL6-12×4 | 2.2 | WLG800-1300 | 0.58 | SYB-S2.2-3V |

61 | WBOG6/3-0.60 | 18 | 60 | 40GDL6-12×5 | 2.2 | WLG800-1300 | 0.58 | SYB-S2.2-3V |

62 | WBOG6/3-0.72 | 18 | 72 | 40GDL6-12×6 | 3 | WLG800-1300 | 0.58 | SYB-S3-3V |

63 | WBOG6/3-0.84 | 18 | 84 | 40GDL6-12×7 | 3 | WLG800-1300 | 0.58 | SYB-S3-3V |

64 | WBOG6/3-0.96 | 18 | 96 | 40GDL6-12×8 | 4 | WLG800-1300 | 0.58 | SYB-S4-3V |

65 | WBOG6/3-1.08 | 18 | 108 | 40GDL6-12×9 | 4 | WLG800-1300 | 0.58 | SYB-S4-3V |

66 | WBOG6/3-1.20 | 18 | 120 | 40GDL6-12×10 | 4 | WLG800-1300 | 0.58 | SYB-S4-3V |

67 | WBOG6/3-1.32 | 18 | 132 | 40GDL6-12×11 | 5.5 | WLG800-1300 | 0.58 | SYB-S5.5-3V |

68 | WBOG6/3-1.44 | 18 | 144 | 40GDL6-12×12 | 5.5 | WLG800-1300 | 0.58 | SYB-S5.5-3V |

69 | WBOG6/3-1.56 | 18 | 156 | 40GDL6-12×13 | 7.5 | WLG800-1300 | 0.58 | SYB-S7.5-3V |

70 | WBOG6/3-1.68 | 18 | 168 | 40GDL6-12×14 | 7.5 | WLG800-1300 | 0.58 | SYB-S7.5-3V |

71 | WBOG6/3-1.80 | 18 | 180 | 40GDL6-12×15 | 7.5 | WLG800-1300 | 0.58 | SYB-S7.5-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

72 | WBOG12/3-0.30 | 36 | 30 | 50GDL12-15×2 | 2.2 | WLG1000-1600 | 1.1 | SYB-S2.2-3V |

73 | WBOG12/3-0.45 | 36 | 45 | 50GDL12-15×3 | 3 | WLG1000-1600 | 1.1 | SYB-S3-3V |

74 | WBOG12/3-0.60 | 36 | 60 | 50GDL12-15×4 | 4 | WLG1000-1600 | 1.1 | SYB-S4-3V |

75 | WBOG12/3-0.75 | 36 | 75 | 50GDL12-15×5 | 5.5 | WLG1000-1600 | 1.1 | SYB-S5.5-3V |

76 | WBOG12/3-0.90 | 36 | 90 | 50GDL12-15×6 | 5.5 | WLG1000-1600 | 1.1 | SYB-S5.5-3V |

77 | WBOG12/3-1.05 | 36 | 105 | 50GDL12-15×7 | 7.5 | WLG1000-1600 | 1.1 | SYB-S7.5-3V |

78 | WBOG12/3-1.20 | 36 | 120 | 50GDL12-15×8 | 7.5 | WLG1000-1600 | 1.1 | SYB-S7.5-3V |

79 | WBOG12/3-1.35 | 36 | 135 | 50GDL12-15×9 | 11 | WLG1000-1600 | 1.1 | SYB-S11-3V |

80 | WBOG12/3-1.50 | 36 | 150 | 50GDL12-15×10 | 11 | WLG1000-1600 | 1.1 | SYB-S11-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

81 | WBOG18/3-0.30 | 54 | 30 | 50GDL18-15×2 | 3 | WLG1200-2000 | 2.0 | SYB-S3-3V |

82 | WBOG18/3-0.45 | 54 | 45 | 50GDL18-15×3 | 4 | WLG1200-2000 | 2.0 | SYB-S4-3V |

83 | WBOG18/3-0.60 | 54 | 60 | 50GDL18-15×4 | 5.5 | WLG1200-2000 | 2.0 | SYB-S5.5-3V |

84 | WBOG18/3-0.75 | 54 | 75 | 50GDL18-15×5 | 7.5 | WLG1200-2000 | 2.0 | SYB-S7.5-3V |

85 | WBOG18/3-0.90 | 54 | 90 | 50GDL18-15×6 | 7.5 | WLG1200-2000 | 2.0 | SYB-S7.5-3V |

86 | WBOG18/3-1.05 | 54 | 105 | 50GDL18-15×7 | 11 | WLG1200-2000 | 2.0 | SYB-S11-3V |

87 | WBOG18/3-1.20 | 54 | 120 | 50GDL18-15×8 | 11 | WLG1200-2000 | 2.0 | SYB-S11-3V |

88 | WBOG18/3-1.35 | 54 | 135 | 50GDL18-15×9 | 15 | WLG1200-2000 | 2.0 | SYB-S15-3V |

89 | WBOG18/3-1.50 | 54 | 150 | 50GDL18-15×10 | 15 | WLG1200-2000 | 2.0 | SYB-S15-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

90 | WBOG24/3-0.24 | 72 | 24 | 65GDL24-12×2 | 3 | WLG1200-2000 | 2.0 | SYB-S3-3V |

91 | WBOG24/3-0.36 | 72 | 36 | 65GDL24-12×3 | 4 | WLG1200-2000 | 2.0 | SYB-S4-3V |

92 | WBOG24/3-0.48 | 72 | 48 | 65GDL24-12×4 | 5.5 | WLG1200-2000 | 2.0 | SYB-S5.5-3V |

93 | WBOG24/3-0.60 | 72 | 60 | 65GDL24-12×5 | 7.5 | WLG1200-2000 | 2.0 | SYB-S7.5-3V |

94 | WBOG24/3-0.72 | 72 | 72 | 65GDL24-12×6 | 7.5 | WLG1200-2000 | 2.0 | SYB-S7.5-3V |

95 | WBOG24/3-0.84 | 72 | 84 | 65GDL24-12×7 | 11 | WLG1200-2000 | 2.0 | SYB-S11-3V |

96 | WBOG24/3-0.96 | 72 | 96 | 65GDL24-12×8 | 11 | WLG1200-2000 | 2.0 | SYB-S11-3V |

97 | WBOG24/3-1.08 | 72 | 108 | 65GDL24-12×9 | 15 | WLG1200-2000 | 2.0 | SYB-S15-3V |

98 | WBOG24/3-1.20 | 72 | 120 | 65GDL24-12×10 | 15 | WLG1200-2000 | 2.0 | SYB-S15-3V |

99 | WBOG24/3-1.32 | 72 | 132 | 65GDL24-12×11 | 15 | WLG1200-2000 | 2.0 | SYB-S15-3V |

100 | WBOG24/3-1.44 | 72 | 144 | 65GDL24-12×12 | 18.5 | WLG1200-2000 | 2.0 | SYB-S18.5-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

101 | WBOG36/3-0.24 | 108 | 24 | 80GDL36-12×2 | 4 | WLG1400-2500 | 3.5 | SYB-S4-3V |

102 | WBOG36/3-0.36 | 108 | 36 | 80GDL36-12×3 | 5.5 | WLG1400-2500 | 3.5 | SYB-S5.5-3V |

103 | WBOG36/3-0.48 | 108 | 48 | 80GDL36-12×4 | 7.5 | WLG1400-2500 | 3.5 | SYB-S7.5-3V |

104 | WBOG36/3-0.60 | 108 | 60 | 80GDL36-12×5 | 11 | WLG1400-2500 | 3.5 | SYB-S11-3V |

105 | WBOG36/3-0.72 | 108 | 72 | 80GDL36-12×6 | 11 | WLG1400-2500 | 3.5 | SYB-S11-3V |

106 | WBOG36/3-0.84 | 108 | 84 | 80GDL36-12×7 | 15 | WLG1400-2500 | 3.5 | SYB-S15-3V |

107 | WBOG36/3-0.96 | 108 | 96 | 80GDL36-12×8 | 15 | WLG1400-2500 | 3.5 | SYB-S15-3V |

108 | WBOG36/3-1.08 | 108 | 108 | 80GDL36-12×9 | 18.5 | WLG1400-2500 | 3.5 | SYB-S18.5-3V |

109 | WBOG36/3-1.20 | 108 | 120 | 80GDL36-12×10 | 18.5 | WLG1400-2500 | 3.5 | SYB-S18.5-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

110 | WBOG54/3-0.28 | 162 | 28 | 80GDL54-14×2 | 7.5 | WLG1400-2500 | 3.5 | SYB-S7.5-3V |

111 | WBOG54/3-0.42 | 162 | 42 | 80GDL54-14×3 | 11 | WLG1400-2500 | 3.5 | SYB-S11-3V |

112 | WBOG54/3-0.56 | 162 | 56 | 80GDL54-14×4 | 15 | WLG1400-2500 | 3.5 | SYB-S15-3V |

113 | WBOG54/3-0.70 | 162 | 70 | 80GDL54-14×5 | 18.5 | WLG1400-2500 | 3.5 | SYB-S18.5-3V |

114 | WBOG54/3-0.84 | 162 | 84 | 80GDL54-14×6 | 18.5 | WLG1400-2500 | 3.5 | SYB-S18.5-3V |

115 | WBOG54/3-0.98 | 162 | 98 | 80GDL54-14×7 | 22 | WLG1400-2500 | 3.5 | SYB-S22-3V |

116 | WBOG54/3-1.12 | 162 | 112 | 80GDL54-14×8 | 30 | WLG1400-2500 | 3.5 | SYB-S30-3V |

117 | WBOG54/3-1.26 | 162 | 126 | 80GDL54-14×9 | 30 | WLG1400-2500 | 3.5 | SYB-S30-3V |

118 | WBOG54/3-1.40 | 162 | 140 | 80GDL54-14×10 | 37 | WLG1400-2500 | 3.5 | SYB-S37-3V |

119 | WBOG72/3-0.28 | 216 | 28 | 100GDL72-14×2 | 11 | WLG1600-3300 | 6.0 | SYB-S11-3V |

120 | WBOG72/3-0.42 | 216 | 42 | 100GDL72-14×3 | 15 | WLG1600-3300 | 6.0 | SYB-S15-3V |

121 | WBOG72/3-0.56 | 216 | 56 | 100GDL72-14×4 | 18.5 | WLG1600-3300 | 6.0 | SYB-S18.5-3V |

122 | WBOG72/3-0.70 | 216 | 70 | 100GDL72-14×5 | 22 | WLG1600-3300 | 6.0 | SYB-S22-3V |

123 | WBOG72/3-0.84 | 216 | 84 | 100GDL72-14×6 | 30 | WLG1600-3300 | 6.0 | SYB-S30-3V |

124 | WBOG72/3-0.98 | 216 | 98 | 100GDL72-14×7 | 30 | WLG1600-3300 | 6.0 | SYB-S30-3V |

125 | WBOG72/3-1.12 | 216 | 112 | 100GDL72-14×8 | 37 | WLG1600-3300 | 6.0 | SYB-S37-3V |

126 | WBOG72/3-1.26 | 216 | 126 | 100GDL72-14×9 | 37 | WLG1600-3300 | 6.0 | SYB-S37-3V |

127 | WBOG72/3-1.40 | 216 | 140 | 100GDL72-14×10 | 45 | WLG1600-3300 | 6.0 | SYB-S45-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

128 | WBOG108/3-0.40 | 324 | 40 | 125GDL100-20×2 | 18.5 | WLG1600-3300 | 6.0 | SYB-S18.5-3V |

129 | WBOG108/3-0.60 | 324 | 60 | 125GDL100-20×3 | 30 | WLG1600-3300 | 6.0 | SYB-S30-3V |

130 | WBOG108/3-0.80 | 324 | 80 | 125GDL100-20×4 | 37 | WLG1600-3300 | 6.0 | SYB-S37-3V |

131 | WBOG108/3-1.00 | 324 | 100 | 125GDL100-20×5 | 45 | WLG1600-3300 | 6.0 | SYB-S45-3V |

132 | WBOG108/3-1.20 | 324 | 120 | 125GDL100-20×6 | 55 | WLG1600-3300 | 6.0 | SYB-S55-3V |

133 | WBOG108/3-1.40 | 324 | 140 | 125GDL100-20×7 | 75 | WLG1600-3300 | 6.0 | SYB-S75-3V |

134 | WBOG108/3-1.60 | 324 | 160 | 125GDL100-20×8 | 75 | WLG1600-3300 | 6.0 | SYB-S75-3V |

135 | WBOG108/3-1.80 | 324 | 180 | 125GDL100-20×9 | 90 | WLG1600-3300 | 6.0 | SYB-S90-3V |

136 | WBOG108/3-2.00 | 324 | 200 | 125GDL100-20×10 | 90 | WLG1600-3300 | 6.0 | SYB-S90-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

137 | WBOG162/3-0.40 | 486 | 40 | 150GDL160-20×2 | 30 | WLG2000-4000 | 11.5 | SYB-S30-3V |

138 | WBOG162/3-0.60 | 486 | 60 | 150GDL160-20×3 | 37 | WLG2000-4000 | 11.5 | SYB-S37-3V |

139 | WBOG162/3-0.80 | 486 | 80 | 150GDL160-20×4 | 55 | WLG2000-4000 | 11.5 | SYB-S55-3V |

140 | WBOG162/3-1.00 | 486 | 100 | 150GDL160-20×5 | 75 | WLG2000-4000 | 11.5 | SYB-S75-3V |

141 | WBOG162/3-1.20 | 486 | 120 | 150GDL160-20×6 | 75 | WLG2000-4000 | 11.5 | SYB-S75-3V |

142 | WBOG162/3-1.40 | 486 | 140 | 150GDL160-20×7 | 90 | WLG2000-4000 | 11.5 | SYB-S90-3V |

143 | WBOG162/3-1.60 | 486 | 160 | 150GDL160-20×8 | 110 | WLG2000-4000 | 11.5 | SYB-S110-3V |

144 | WBOG162/3-1.80 | 486 | 180 | 150GDL160-20×9 | 110 | WLG2000-4000 | 11.5 | SYB-S110-3V |

145 | WBOG162/3-2.00 | 486 | 200 | 150GDL160-20×10 | 132 | WLG2000-4000 | 11.5 | SYB-S132-3V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

146 | WBOL6.3/2-0.20 | 12.6 | 20 | LS40-20/2/1.5 | 1.5 | WLG600-1000 | 0.25 | SYB-S1.5-2V |

147 | WBOL6.3/2-0.28 | 11.8 | 28 | LS40-28/2/2.2 | 2.2 | WLG600-1000 | 0.25 | SYB-S2.2-2V |

148 | WBOL6.3/2-0.38 | 11 | 38 | LS40-38/2/3 | 3 | WLG600-1000 | 0.25 | SYB-S3-2V |

149 | WBOL6.3/2-0.50 | 12.6 | 50 | LS40-50/2/4 | 5.5 | WLG600-1000 | 0.25 | SYB-S5.5-2V |

150 | WBOL6.3/2-0.60 | 11 | 60 | LS40-60/2/4 | 7.5 | WLG600-1000 | 0.25 | SYB-S7.5-2V |

151 | WBOL6.3/2-0.70 | 11.8 | 70 | LS40-70/2/5.5 | 7.5 | WLG600-1000 | 0.25 | SYB-S7.5-2V |

152 | WBOL6.3/2-0.80 | 12.6 | 80 | LS40-80/2/7.5 | 11 | WLG600-1000 | 0.25 | SYB-S11-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

153 | WBOL12.5/2-0.125 | 25 | 12.5 | LS50-12.5/2/1.1 | 1.1 | WLG800-1300 | 0.58 | SYB-S1.1-2V |

154 | WBOL12.5/2-0.20 | 25 | 20 | LS50-20/2/1.5 | 1.5 | WLG800-1300 | 0.58 | SYB-S1.5-2V |

155 | WBOL11/2-0.28 | 22 | 28 | LS50-28/2/2.2 | 2.2 | WLG800-1300 | 0.58 | SYB-S2.2-2V |

156 | WBOL10/2-0.35 | 20 | 35 | LS50-35/2/3 | 3 | WLG800-1300 | 0.58 | SYB-S3-2V |

157 | WBOL12.5/2-0.5 | 25 | 50 | LS50-50/2/5.5 | 5.5 | WLG800-1300 | 0.58 | SYB-S5.5-2V |

158 | WBOL10/2-0.6 | 20 | 60 | LS50-60/2/7.5 | 7.5 | WLG800-1300 | 0.58 | SYB-S7.5-2V |

159 | WBOL11/2-0.7 | 22 | 70 | LS50-70/2/7.5 | 7.5 | WLG800-1300 | 0.58 | SYB-S7.5-2V |

160 | WBOL12.5/2-0.8 | 25 | 80 | LS50-80/2/11 | 11 | WLG800-1300 | 0.58 | SYB-S11-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

161 | WBOL25/2-0.125 | 50 | 12.5 | LS65-12.5/2/1.5 | 1.5 | WLG1000-1600 | 1.1 | SYB-S1.5-2V |

162 | WBOL23.4/2-0.28 | 46.8 | 28 | LS65-28/2/4 | 4 | WLG1000-1600 | 1.1 | SYB-S4-2V |

163 | WBOL20/2-0.38 | 40 | 38 | LS65-38/2/5.5 | 5.5 | WLG1000-1600 | 1.1 | SYB-S5.5-2V |

164 | WBOL25/2-0.50 | 50 | 50 | LS65-50/2/7.5 | 7.5 | WLG1000-1600 | 1.1 | SYB-S7.5-2V |

165 | WBOL20/2-0.60 | 40 | 60 | LS65-60/2/11 | 11 | WLG1000-1600 | 1.1 | SYB-S11-2V |

166 | WBOL23.4/2-0.70 | 46.8 | 70 | LS65-70/2/11 | 11 | WLG1000-1600 | 1.1 | SYB-S11-2V |

167 | WBOL25/2-0.80 | 50 | 80 | LS65-80/2/15 | 15 | WLG1000-1600 | 1.1 | SYB-S15-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

168 | WBOL50/2-0.125 | 100 | 12.5 | LS80-12.5/2/3 | 3 | WLG1200-2000 | 2.0 | SYB-S3-2V |

169 | WBOL46.8/2-0.28 | 93.6 | 28 | LS80-28/2/7.5 | 7.5 | WLG1200-2000 | 2.0 | SYB-S7.5-2V |

170 | WBOL42/2-0.38 | 84 | 38 | LS80-38/2/7.5 | 7.5 | WLG1200-2000 | 2.0 | SYB-S7.5-2V |

171 | WBOL50/2-0.50 | 100 | 50 | LS80-50/2/15 | 15 | WLG1200-2000 | 2.0 | SYB-S15-2V |

172 | WBOL43/2-0.60 | 86 | 60 | LS80-60/2/15 | 15 | WLG1200-2000 | 2.0 | SYB-S15-2V |

173 | WBOL46.8/2-0.70 | 93.6 | 70 | LS80-70/2/15 | 18.5 | WLG1200-2000 | 2.0 | SYB-S18.5-2V |

174 | WBOL50/2-0.80 | 100 | 80 | LS80-80/2/22 | 22 | WLG1200-2000 | 2.0 | SYB-S22-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

175 | WBOL100/2-0.125 | 200 | 12.5 | LS100-12.5/2/5.5 | 5.5 | WLG1400-2500 | 3.5 | SYB-S5.5-2V |

176 | WBOL93/2-0.28 | 186 | 28 | LS100-28/2/11 | 11 | WLG1400-2500 | 3.5 | SYB-S11-2V |

177 | WBOL86/2-0.38 | 172 | 38 | LS100-38/2/15 | 15 | WLG1400-2500 | 3.5 | SYB-S15-2V |

178 | WBOL100/2-0.50 | 200 | 50 | LS100-50/2/22 | 22 | WLG1400-2500 | 3.5 | SYB-S22-2V |

179 | WBOL86/2-0.60 | 172 | 60 | LS100-60/2/30 | 30 | WLG1400-2500 | 3.5 | SYB-S30-2V |

180 | WBOL93/2-0.70 | 176 | 70 | LS100-70/2/30 | 30 | WLG1400-2500 | 3.5 | SYB-S30-2V |

181 | WBOL100/2-0.80 | 200 | 80 | LS100-80/2/37 | 37 | WLG1400-2500 | 3.5 | SYB-S37-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

182 | WBOL160/2-0.125 | 320 | 12.5 | LS125-12.5/2/11 | 11 | WLG1600-3300 | 6.0 | SYB-S11-2V |

183 | WBOL160/2-0.20 | 320 | 20 | LS125-20/2/15 | 15 | WLG1600-3300 | 6.0 | SYB-S15-2V |

184 | WBOL187/2-0.28 | 374 | 28 | LS125-28/2/22 | 22 | WLG1600-3300 | 6.0 | SYB-S22-2V |

185 | WBOL200/2-0.32 | 400 | 32 | LS125-32/2/30 | 30 | WLG1600-3300 | 6.0 | SYB-S30-2V |

186 | WBOL187/2-0.44 | 374 | 44 | LS125-44/2/30 | 30 | WLG1600-3300 | 6.0 | SYB-S37-2V |

187 | WBOL200/2-0.50 | 400 | 50 | LS125-50/2/45 | 45 | WLG1600-3300 | 6.0 | SYB-S45-2V |

188 | WBOL172/2-0.60 | 344 | 60 | LS125-60/2/45 | 45 | WLG1600-3300 | 6.0 | SYB-S45-2V |

189 | WBOL187/2-0.70 | 374 | 70 | LS125-70/2/55 | 55 | WLG1600-3300 | 6.0 | SYB-S55-2V |

190 | WBOL200/2-0.80 | 400 | 80 | LS125-80/2/75 | 75 | WLG1600-3300 | 6.0 | SYB-S75-2V |

number | Type | Capacity | Head | Pump type | Power | Steady flow tank | 11.5Control tank | |

Model | flow | lift | Pump type | 功率 | Specifications(Dg-L) | volume | Distribution control cabinet | |

191 | WBOL200/2-0.125 | 400 | 12.5 | LS150-12.5/4/15 | 15 | WLG2000-4000 | 11.5 | SYB-S15-2V |

192 | WBOL200/2-0.20 | 400 | 20 | LS150-20/4/18.5 | 18.5 | WLG2000-4000 | 11.5 | SYB-S18.5-2V |

193 | WBOL150/2-0.28 | 300 | 28 | LS150-28/4/18.5 | 18.5 | WLG2000-4000 | 11.5 | SYB-S18.5-2V |

194 | WBOL200/2-0.32 | 400 | 32 | LS150-32/4/30 | 30 | WLG2000-4000 | 11.5 | SYB-S30-2V |

195 | WBOL150/2-0.44 | 300 | 44 | LS150-44/4/30 | 30 | WLG2000-4000 | 11.5 | SYB-S30-2V |

196 | WBOL200/2-0.50 | 400 | 50 | LS150-50/4/45 | 45 | WLG2000-4000 | 11.5 | SYB-S45-2V |

197 | WBOL172/2-0.60 | 332 | 60 | LS150-60/2/45 | 45 | WLG2000-4000 | 11.5 | SYB-S45-2V |

198 | WBOL182/2-0.70 | 364 | 70 | LS150-70/2/55 | 55 | WLG2000-4000 | 11.5 | SYB-S55-2V |

199 | WBOL200/2-0.80 | 400 | 80 | LS150-80/2/75 | 75 | WLG2000-4000 | 11.5 | SYB-S75-2V |