Hot Online

400-027-6688

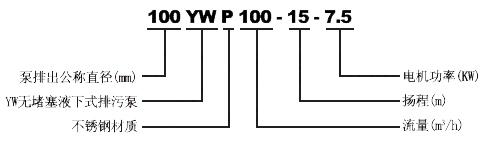

Model significance

Product profile

The series of sewage pump is the introduction of the Federal Republic of Germany ABS Pump Company advanced technology, through absorption, transformation and development, the performance indicators have reached the national standard of similar products. Due to the unique single (double) channel impeller, sewage capability, can effectively by 5 times and the diameter of fiber pump caliber caliber pump solid particles 50%, dynamic seal with hard alloy mechanical two special material sealing device, made of cast iron and stainless steel.

Product features

1, using the double blade impeller structure, greatly improving the ability through the dirt

Using a new type of friction sealing 2, mechanical, and long into the oil chamber operation;

3, compact structure, small size, small sound, energy saving effect is obvious, easy maintenance, convenient user replacement;

4, automatic control cabinet can be based on the need to change the liquefaction, automatic control of the pump to move and stop, no special care, the use of extremely convenient;

5, according to the user needs to install the way, it to the installation, maintenance of great convenience, people do not have to enter the sewage pit;

6, can be used in the design range, and to ensure that the motor will not overload;

7, the pump with outdoor motor without pump room, can be installed directly and save money for outdoor use;

Product use

YW series of non clogging sewage pump used for factory commercialheavily pollutedwaste water, the main residential area of the sewage station, city sewage treatment plant to send water system, air defense system drainage station, tap water plant water supply equipment, hotel, hospital sewage, municipal engineering construction, mining completewithmachine, biogas digesters in rural areas irrigation, industry, sewage containing particles, dirt, can also be used to clean water and weak corrosive medium.

Use conditions

The ambient temperature is less than or equal to A, the pump 40 degrees, humidity is less than 95%; altitude less than 1000 meters.

B, the medium temperature is not more than 60 DEG C, medium severe for the 1 ~ 1.3kg/dm3.

C, cast iron material use range PH5 ~ 9.

D, stainless steel material can be used in general corrosive medium. The ambient temperature is less than or equal to A, the pump 40 degrees, humidity is less than 95%; altitude less than 1000 meters.

B, the medium temperature is not more than 60 DEG C, medium severe for the 1 ~ 1.3kg/dm3.

C, cast iron material use range PH5 ~ 9.

D, stainless steel material can be used in general corrosive medium.

E, the use of the environment is not more than 1000 meters above sea level, more than the above conditions, should be made in order to provide you with more reliable products.

Note: if the user has special temperature, medium and other requirements, please specify the details of the delivery medium in order to provide more reliable products.

Structural sketch map

| |||

1 | 电机 | 12 | 油室 |

2 | 联轴器 | 13 | 油封 |

3 | 联接端盖 | 14 | 泵盖 |

4 | 轴承压盖 | 15 | 叶轮螺母 |

5 | 安装平盘 | 16 | 叶轮 |

6 | 轴承座 | 17 | 出水弯管 |

7 | 轴承 | 18 | 泵体 |

8 | 加长轴 | 19 | 耐磨体 |

9 | 支撑管 | 20 | 底座 |

10 | 轴承 | 21 | 出液管 |

11 | 机械密封 |

|

|

Model | caliber | flow | lift | speed | power | efficiency |

mm | m3/h | M | r/min | kw | % | |

25-8-22-1.1 | 25 | 8 | 22 | 2900 | 1.1 | 45 |

32-12-15-1.1 | 32 | 12 | 15 | 2900 | 1.1 | |

40-15-15-1.5 | 40 | 15 | 15 | 2900 | 1.5 | 54 |

40-15-30-2.2 | 40 | 15 | 30 | 2900 | 2.2 | 54 |

50-20-7-0.75 | 50 | 20 | 7 | 2900 | 0.75 | 51 |

50-10-10-0.75 | 50 | 10 | 10 | 2900 | 0.75 | 52 |

50-20-15-1.5 | 50 | 20 | 15 | 290 | 1.5 | 53 |

50-15-25-2.2 | 50 | 15 | 25 | 2900 | 2.2 | 54 |

50-18-30-3 | 50 | 18 | 30 | 2900 | 3 | 55 |

50-40-15-4 | 50 | 40 | 15 | 2900 | 4 | 55 |

50-25-32-5.5 | 50 | 25 | 32 | 2900 | 5.5 | 55 |

50-20-40-7.5 | 50 | 50 | 20 | 2900 | 7.5 | 58 |

65-25-15-2.2 | 65 | 25 | 15 | 2900 | 2.2 | 50 |

65-37-13-3 | 65 | 37 | 13 | 2900 | 3 | 57 |

65-25-30-4 | 65 | 25 | 30 | 2900 | 4 | 61 |

65-30-40-7.5 | 65 | 30 | 40 | 2900 | 7.5 | 56 |

65-35-50-11 | 65 | 35 | 50 | 2900 | 11 | 45 |

65-35-60-15 | 65 | 35 | 60 | 2900 | 15 | 65 |

80-60-13-5.5 | 80 | 60 | 13 | 2900 | 5.5 | 67 |

80-40-7-2.2 | 80 | 40 | 7 | 1450 | 2.2 | 59 |

80-43-13-3 | 80 | 43 | 13 | 2900 | 3 | 70 |

80-40-15-4 | 80 | 40 | 15 | 2900 | 4 | 61 |

80-65-25-7.5 | 80 | 65 | 25 | 2900 | 7.5 | 63 |

100-80-10-4 | 100 | 100 | 10 | 1450 | 4 | 65 |

Model | caliber | flow | lift | speed | power | efficiency |

mm | m3/h | M | r/min | kw | % | |

100-110-10-5.5 | 100 | 110 | 10 | 1450 | 5.5 | 65 |

100-100-15-7.5 | 100 | 100 | 15 | 1450 | 7.5 | 68 |

100-80-20-7.5 | 100 | 80 | 20 | 1450 | 7.5 | 65 |

100-100-25-11 | 100 | 100 | 25 | 1450 | 11 | 70 |

100-100-30-15 | 100 | 100 | 30 | 1450 | 15 | 65 |

100-100-35-18.5 | 100 | 100 | 35 | 1450 | 18.5 | 68 |

125-130-15-11 | 125 | 130 | 15 | 1450 | 11 | 72 |

125-130-20-15 | 125 | 130 | 20 | 1450 | 15 | 75 |

150-145-9-7.5 | 150 | 145 | 9 | 1450 | 7.5 | 76 |

150-180-15-15 | 150 | 180 | 15 | 1450 | 15 | 69 |

150-180-20-18.5 | 150 | 180 | 20 | 1450 | 18.5 | 72 |

150-180-25-22 | 150 | 180 | 25 | 1450 | 22 | 78 |

150-130-30-22 | 150 | 130 | 30 | 1450 | 22 | 78 |

150-180-30-30 | 150 | 180 | 30 | 1450 | 30 | 78 |

150-200-30-37 | 150 | 200 | 30 | 1450 | 37 | 73 |

200-300-7-11 | 200 | 300 | 7 | 980 | 11 | 66 |

200-250-11-15 | 200 | 250 | 11 | 1450 | 15 | 64 |

200-250-15-18.5 | 200 | 250 | 15 | 1450 | 18.5 | 73 |

200-400-10-22 | 200 | 400 | 10 | 1450 | 22 | 75 |

200-400-13-30 | 200 | 400 | 13 | 14501 | 30 | 76 |

200-300-15-22 | 200 | 300 | 15 | 1450 | 22 | 76 |

200-250-22-30 | 200 | 250 | 22 | 1450 | 30 | 71 |

200-350-25-37 | 200 | 350 | 25 | 1450 | 37 | 71 |

200-400-30-45 | 200 | 400 | 30 | 1450 | 45 | 74 |

Model | caliber | flow | lift | speed | power | efficiency |

mm | m3/h | M | r/min | kw | % | |

250-600-9-30 | 250 | 600 | 9 | 980 | 30 | 78 |

250-600-12-37 | 250 | 600 | 12 | 1450 | 37 | 76 |

250-600-15-45 | 250 | 600 | 15 | 1450 | 45 | 73 |

250-600-20-55 | 250 | 600 | 20 | 1450 | 55 | 73 |

250-600-25-75 | 250 | 600 | 25 | 1450 | 75 | 71 |

300-800-12-45 | 300 | 800 | 12 | 980 | 45 | 74 |

300-480-15-45 | 300 | 480 | 15 | 1450 | 45 | 66 |

300-800-15-55 | 300 | 800 | 15 | 1450 | 55 | 73 |

300-600-20-55 | 300 | 600 | 20 | 1450 | 55 | 73 |

300-800-20-75 | 300 | 800 | 20 | 1450 | 75 | 75 |

300-950-20-90 | 300 | 950 | 20 | 1450 | 90 | 76 |

300-1000-25-110 | 300 | 1000 | 25 | 1450 | 110 | 76 |

300-1100-10-55 | 300 | 1100 | 10 | 1450 | 55 | 73 |

350-1500-15-90 | 350 | 1500 | 15 | 740 | 90 | 87 |

350-1200-18-90 | 350 | 1200 | 18 | 980 | 90 | 85 |

350-1100-28-132 | 350 | 1100 | 28 | 980 | 132 | 84 |

350-1000-36-160 | 350 | 1000 | 36 | 980 | 160 | 84 |

400-1760-7.5-55 | 400 | 1760 | 7.5 | 980 | 55 | 83 |

400-1500-10-75 | 400 | 1500 | 10 | 980 | 75 | 86 |

400-2000-13-110 | 400 | 2000 | 13 | 980 | 110 | 84 |

400-2000-15-132 | 400 | 2000 | 15 | 980 | 132 | 83 |

400-1700-22-160 | 400 | 1700 | 22 | 980 | 160 | 83 |

400-1500-26-160 | 400 | 1500 | 26 | 980 | 160 | 84 |

Model | caliber | flow | lift | speed | power | efficiency |

mm | m3/h | M | r/min | kw | % | |

400-1700-30-200 | 400 | 1700 | 30 | 980 | 200 | 86 |

400-1800-32-250 | 400 | 1800 | 32 | 980 | 250 | 82 |

500-2500-10-110 | 500 | 2500 | 10 | 740 | 110 | 85 |

500-2600-15-160 | 500 | 2600 | 15 | 740 | 160 | 84 |

500-2400-22-220 | 500 | 2400 | 22 | 740 | 220 | 85 |

500-2650-24-250 | 500 | 2650 | 24 | 740 | 250 | 85 |