Hot Online

400-027-6688

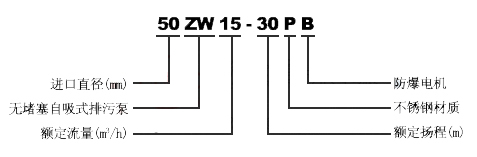

Model significance

Product profile

ZW series self-priming sewage pump is a structure developed based on similar products at home and abroad study repeatedly on the technology of new products, the set of self suction pump and non clogging sewage in one, the axial circumfluence form, and the pump body. The unique design of the impeller, as the general self absorption water pump do not need to install the valve and irrigation water, and suction with large particles and long fiber solid impurities unwrapping. Widely used in municipal sewage works, pond aquaculture waste treatment, waste precipitation of impurities, impurity pump light industry, papermaking, food, chemical, pharmaceutical, power, and other chemical slurry mixture to the medium quality.

The pump is compared with the domestic similar products, has the advantages of simple structure, good self-priming performance, (self-priming height up to 5M), sewage capability, high efficiency and energy saving, convenient maintenance (and can completely replace the WQ, QW submerged pump) and other characteristics, the sewage pump series products is the first domestic. The domestic leading indicators to reach the international advanced level. Has broad application market development prospects.

Product features

1, using the double blade impeller structure, greatly improving the ability through the dirt

Using a new type of friction sealing 2, mechanical, and long into the oil chamber operation;

3, compact structure, small size, small sound, energy saving effect is obvious, easy maintenance, convenient user replacement;

4, automatic control cabinet can be based on the need to change the liquefaction, automatic control of the pump to move and stop, no special care, the use of extremely convenient;

5, according to the user needs to install the way, it to the installation, maintenance of great convenience, people do not have to enter the sewage pit;

6, can be used in the design range, and to ensure that the motor will not overload;

7, the pump with outdoor motor without pump room, can be installed directly and save money for outdoor use;

Product use

ZW series of non clogging sewage pump used for factory commercialheavily pollutedwaste water, the main residential area of the sewage station, city sewage treatment plant to send water system, air defense system drainage station, tap water plant water supply equipment, hotel, hospital sewage, municipal engineering construction, mining completewithmachine, biogas digesters in rural areas irrigation, industry, sewage containing particles, dirt, can also be used to clean water and weak corrosive medium.

Use conditions

1, the ambient temperature is less than or equal to 50 DEG C, the special requirements of medium temperature are less than 80 to 200 degrees

2, medium pH value of cast iron material for 6--9 grade, stainless steel 2-13.

3, medium weight not more than 1240 kg /m3.

4, self-priming height can not exceed the specified value of 4.5-5.5 meters, the suction pipe length is less than or equal to 10 meters.

5, through the ability to suspend the particle diameter of the pump diameter of 60%, fiber length of pump diameter of 5 times

Structure and working principle

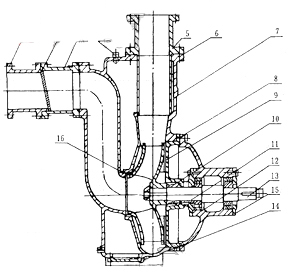

ZW series self-priming sewage pump, mainly by the pump body, impeller, pump cover, mechanical seal, shaft, bearing seat, inlet valve, gas-liquid separation tube, water valve, inlet and exhaust pipe etc.. Pump structure see figure.

The working principle of the pump is characterized in that a liquid storage cavity is arranged in the pump body, and is communicated with the pump working chamber through the reflux hole and the circulating hole below the upper part of the pump, so as to form an axial flow outside mixing system of the pump. After the pump stops working, there is a certain volume of liquid in the pump cavity. When the pump starts, the relevant authorities in the liquid in the impeller under the action of air entrainment is thrown upwards, the liquid separating tube grid reflux into the working cavity through the gas, gas is discharged out of the pump, the pump to form a vacuum, achieve self absorption effect.

Structural sketch map

1 | Inlet nozzle | 9 | Impeller |

2 | Inlet flange | 10 | Mechanical seal |

3 | Inlet valve seat | 11 | The retaining ring |

4 | Water valve | 12 | Bearing seat |

5 | Outlet nozzle | 13 | Pump shaft |

6 | Pump body | 14 | Bearing cap |

7 | Gas-liquid separator | 15 | Bottom cover |

8 | Back cover | 16 | Bolt |

Model | flow | lift | power | speed | efficiency | (NPSH)Required allowance |

| (m3/h) | (M) | (kw) | (r/min) | (%) | (M) |

ZW25-8-15 | 8 | 15 | 2.2 | 2900 | 45 | 2 |

ZW32-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 |

ZW40-20-15 | 20 | 15 | 2.2 | 2900 | 45 | 2.5 |

ZW40-15-30 | 15 | 30 | 3 | 2900 | 48 | 2.5 |

ZW50-10-20 | 10 | 20 | 2.2 | 2900 | 45 | 2.5 |

ZW50-20-15 | 20 | 15 | 2.2 | 2900 | 45 | 2.5 |

ZW50-18-22 | 18 | 22 | 3 | 2900 | 48 | 2.5 |

ZW50-15-30 | 15 | 30 | 3 | 2900 | 48 | 2.5 |

ZW65-30-18 | 30 | 18 | 4 | 2900 | 45 | 2.5 |

ZW65-20-30 | 20 | 30 | 5.5 | 2900 | 45 | 2.5 |

ZW65-25-40 | 25 | 40 | 7.5 | 2900 | 50 | 3 |

ZW80-40-16 | 40 | 16 | 4 | 1450 | 50 | 3 |

ZW80-65-25 | 65 | 25 | 7.5 | 2900 | 50 | 3 |

ZW80-80-35 | 80 | 35 | 15 | 2900 | 45 | 3 |

ZW80-50-60 | 50 | 60 | 22 | 2900 | 55 | 3 |

ZW80-80-45 | 80 | 45 | 22 | 2900 | 55 | 3 |

Model | flow | lift | power | speed | efficiency | (NPSH)Required allowance |

| (m3/h) | (M) | (kw) | (r/min) | (%) | (M) |

ZW100-80-20 | 80 | 20 | 7.5 | 1450 | 53 | 4 |

ZW100-100-15 | 100 | 15 | 7.5 | 1450 | 50 | 4 |

ZW100-100-20 | 100 | 20 | 11 | 1450 | 53 | 4 |

ZW100-100-30 | 100 | 30 | 22 | 2900 | 53 | 4 |

ZW100-80-45 | 80 | 45 | 30 | 2900 | 55 | 4 |

ZW100-80-60 | 80 | 60 | 37 | 290 | 53 | 4 |

ZW100-80-80 | 80 | 80 | 45 | 2900 | 50 | 4 |

ZW125-120-20 | 120 | 20 | 15 | 1450 | 55 | 4.5 |

ZW150-200-15 | 200 | 15 | 15 | 1450 | 60 | 5 |

ZW150-200-20 | 200 | 20 | 22 | 1450 | 60 | 5 |

ZW150-200-28 | 200 | 28 | 30 | 1450 | 65 | 5 |

ZW150-400-25 | 400 | 25 | 55 | 1450 | 45 | 5 |

ZW150-180-40 | 180 | 40 | 55 | 1450 | 65 | 5 |

ZW200-280-12 | 280 | 12 | 22 | 1450 | 62 | 5 |

ZW200-300-18 | 300 | 18 | 37 | 1450 | 59 | 5 |

ZW200-300-25 | 300 | 25 | 45 | 1450 | 55 | 5 |

ZW200-280-28 | 280 | 28 | 55 | 1450 | 61 | 5 |

ZW250-400-22 | 400 | 22 | 55 | 1450 | 65 | 5 |

ZW300-800-14 | 800 | 14 | 55 | 1450 | 61 | 5 |